without disrupting operations

Our solution enables improved work processes through:

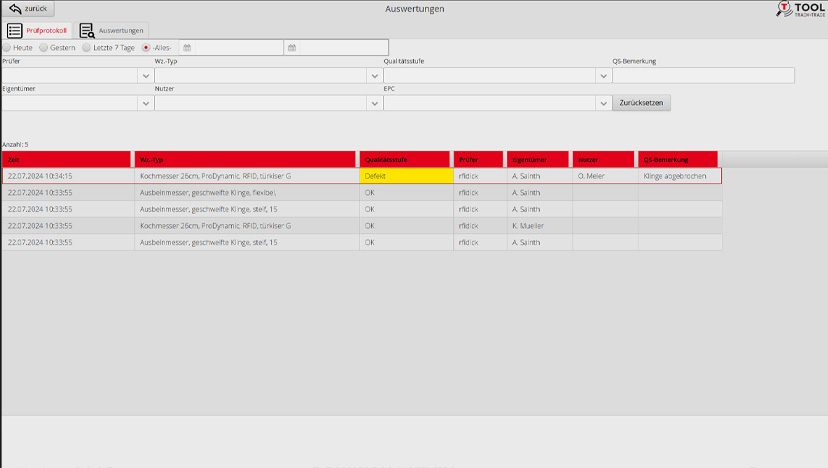

- Monitoring and compliance with guidelines to ensure quality and safety

- Use only approved tools to minimize risks

- Automatic documentation, including recording all tools and checking whether used tools have been replaced with new ones

- Reduction of manual test steps and monitoring procedures

- Modular application options for all registration stations to enable flexible integration

Thanks to our solution, you can make work processes more efficient, ensure compliance with guidelines and reduce manual tasks. The automatic documentation enables reliable data capture and saves you time and effort.

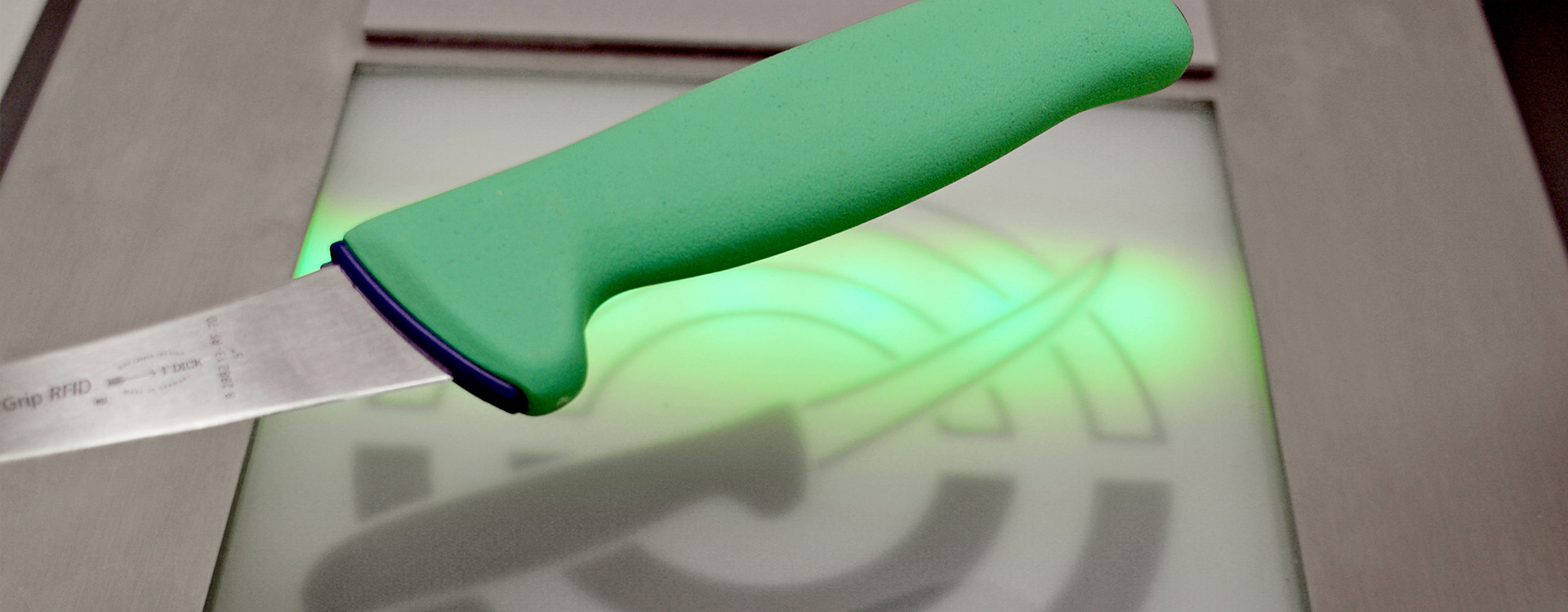

Our RFID system works very simply: it is fully automatic and does not interfere with operational processes.

All tools are recorded in our tool recording system and clearly assigned to a specific employee.

When tools are issued, each employee receives their individual tool basket at the start of the shift after they have been identified. The tools are assigned to the employee automatically and quickly, without annoying waiting times.

During access registration, the employee passes through the hygiene sluice at the entrance. All tools are recorded by the reader system and checked for completeness, allocation and status. An error message is generated if there are any discrepancies. This process takes less than a second, so there are no waiting times.

Whether RFID or data matrix – in shift operation, the tools can be checked on site at any time using a mobile handheld device. If necessary, tools can be replaced, blocked or disposed of. The recorded inspection data is automatically documented.

At the end of the shift, the employees pass through the hygiene sluice at the exit. The tool basket or tools are read using the reader system. Correct tools can be cleaned, sharpened and returned to stock.

In our disposal station, a special module of our RFID system, defective and unusable tools are devalued and then disposed of properly.

Comprehensive monitoring of tool use along the value chain enables traceability, the creation of QA reports and the recording of error messages. This data can be documented and evaluated using reports and statistics.