As with almost every eventful story, our history begins with an ambitious and courageous personality who dares to create something new. In our case, this courageous man was Johann Friedrich Dick, the son of a modest gunsmith, who ventured into self-employment in 1778. This laid the foundations for the success story of the Friedr. Dick company. As with many family businesses, a craft business is the origin of today’s traditional company. It all began with the manufacture of files, later followed by sharpening steels, knives and machines.

Johann Friedrich Dick’s work is guided by his vision: He wanted to produce all types of files himself, from the smallest watchmaker’s file to the large arm file, “in exemplary quality”. The pursuit of the highest quality is therefore something that Friedrich Dick was born with and is still the top priority in all areas of the company today. Find out more about the exciting history of the traditional company Friedr. Dick.

1778

1778Courage in turbulent times: Johann Friedrich Dick founds a file-cutting workshop in Esslingen

After several years on the road, journeyman file cutter Johann Friedrich Dick returns to his home town of Esslingen and sets up his own small workshop. Johann Friedrich Dick’s ambition was already apparent at the beginning of his career. His journeyman’s title was not enough for him and he set off for Nuremberg, where he successfully passed his master craftsman’s examination. These were turbulent times, as the Revolutionary War was raging in the imperial city of Esslingen. This made the decision to set up his own small business all the more courageous. Esslingen is still blessed with a beautiful old town and the house in which this first file-cutting workshop was located has been preserved to this day. A short time later, the original workshop became too small and Johann Friedrich Dick moved his file-cutting business to a larger property, but remained loyal to his home town of Esslingen. Unfortunately, he died at the age of 39 and handed over his workshop to his son, who moved into the Nikolauskapelle chapel five years later. This chapel has also been preserved to this day and is located in the middle of the lively pedestrian zone on a bridge over the Neckar.

1875

1875Growth begins

In the meantime, industrialization had also reached Germany and Paul Friedrich Dick, later Kommerzienrat, took over the company. It was no accident that he mastered the transition from a craft business to an industrial company and the challenges of the time. It was mainly due to the character of Paul Friedrich Dick, who, like many Swabian business leaders, possessed an irrepressible will to create, demonstrated courage and was an absolute organizational talent. He also excelled with his enormous expertise and craftsmanship. Shortly after taking over the workshop, he bought a new, larger property in which the Friedr. Dick file and tool factory soon grew into a small but excellent company. The first file cutting machine in Germany was set up under his management. Paul Friedrich Dick was a man of great courage, ambition and, above all, economic vision. He included other products in his production early on. He was particularly fond of sharpening steels.

Customer focus brings new visions

No customer requirement was ignored by Paul Friedrich Dick. As he had already been successfully supplying sharpening steels to the surrounding butcher’s shops for several years, he expanded his product range once again and now also manufactured other tools, cleavers and knives. Another bold step taken by Paul Friedrich Dick was the purchase of a plot of land near the present-day railroad station in Esslingen. He dared to make the enormous investment in a larger company site and was to be rewarded for his daring. In August 1890, he and his now 100 employees moved into the new premises. The small factory continued to grow and he not only employed his own mechanics to maintain and develop new machines, but also procured test machines to help work out new production methods. From the very beginning, Paul Dick attached particular importance to the quality and function of his products. Even then, in the middle of the 19th century, these were the cornerstones of success that are still firmly anchored in the Friedr. Dick company culture today.

1893

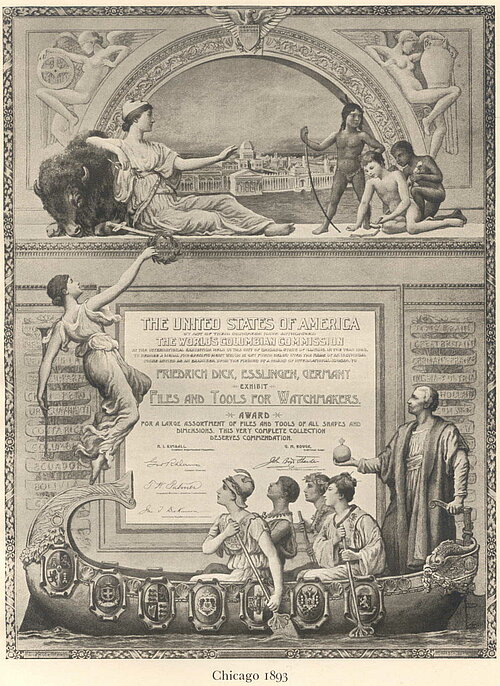

1893The leap across the pond – the World’s Fair in Chicago

In the spring of 1893, Paul Friedrich Dick set off and traveled across the Atlantic to the USA. He presented his files, sharpening steels, tools and knives at the World’s Fair in Chicago, but was also able to establish important business relationships for the distribution of his products. While Paul Friedrich Dick was learning new things and gaining experience in the USA, his factory in Esslingen was honored by a visit from King Wilhelm II of Württemberg. Together with his wife, he marveled at the production facilities and was also interested in the employees of the growing factory. For Paul Friedrich Dick and his employees, the visit was a tremendous honor and word quickly spread. Together with steelworks, he developed special steels for his products, secured patents, created new products and the world-famous F. DICK brand name.

1904

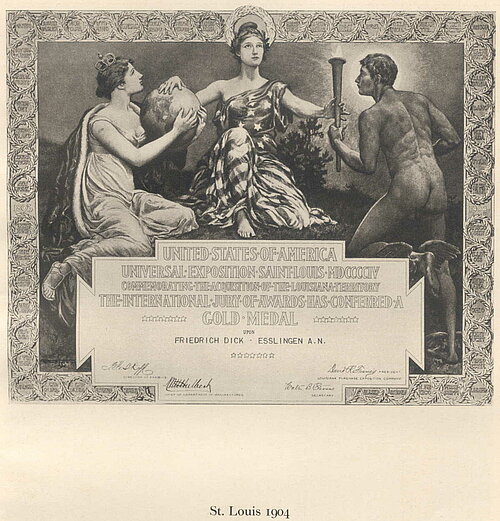

1904St. Louis World’s Fair, USA

There is no question how important the American market is for Friedr. Dick. For the upcoming world exhibition in St. Louis, USA, the suitcases were packed again and the products were also presented there. Further contacts and partnerships were established and Friedr. Dick was honored with a gold medal by an international jury during the exhibition.

1914

1914The setbacks of a success story

The beginning of the First World War also brought hard times for Friedr. Dick. Almost a third of the workforce was drafted into the war and yet the existing supply contracts had to be fulfilled. Files were needed and materials were in short supply. Paul Friedrich Dick, son of our Kommerzienrat, joined the company in 1914, having already worked in the business for several years. Just five years later, he took over the commercial management of the company. With the end of the war and the political and economic collapse of Germany, new challenges also arose for Friedr. Dick. The introduction of the eight-hour working day and the onset of inflation required far-sighted planning and management. The workforce had now grown to 1,200 employees. With the New York stock market crash and the subsequent global economic crisis, Friedr. Dick was also forced to reduce working hours and lay off employees.

The competencies are expanded: The takeover of Wilh. Meeh GmbH, Wiernsheim

Friedr. Dick has always been associated with the skilled trades and has maintained many cooperations with smaller and larger workshops. The company Wilh. Meeh, which manufactured circular metal saws in particular, was also one of Friedr. Dick’s most important partners. After the former owner left the company, Friedr. Dick took over the business without further ado. The strategic importance of this would only become clear later. However, one thing was clear: Friedr. Dick expanded his knowledge and expertise in the field of “cutting and sawing”.

Gloomy times and a ray of hope

Another dark chapter in history also left its mark on Friedr. Dick. While production was able to continue as normal at the beginning of the war, more and more employees were conscripted during the war years and fell victim to the war. In April 1945, the factory premises were severely damaged in bombing raids and production was halted due to a shortage of coal. It was not until the beginning of 1946 that work could be resumed and with the coming economic upswing, things also started to look up again for Friedr.

Foundation of the Bayreuth branch

The course is still set for growth, but there is a shortage of workers in the Swabian town of Esslingen. Large companies such as Daimler and Bosch are located nearby. Friedr. Dick therefore decided to set up another plant in Bayreuth in 1977. In particular, work requiring intensive manual labor, such as the finishing and fine grinding of wooden knife handles, was immediately taken over by the branch plant.

Foundation of the Bayreuth branch

The course is still set for growth, but there is a shortage of workers in the Swabian town of Esslingen. Large companies such as Daimler and Bosch are located nearby. Friedr. Dick therefore decided to set up another plant in Bayreuth in 1977. In particular, work requiring intensive manual labor, such as the finishing and fine grinding of wooden knife handles, was immediately taken over by the branch plant.

1989

1989Wilhelm Leuze, great-grandson of Paul Dick, takes over the management of the company

After almost 15 years, a direct descendant of Kommerzienrat Paul Dick takes over the management of the company again: Mr. Wilhelm Leuze, great-grandson of Paul Dick, is now pulling the strings and managing the traditional company. Wilhelm Leuze, who had initially worked in a completely different industry, joined the company for a few days each month. It quickly became clear to him that one thing above all was important in order to keep the company on course for growth: strategically sensible investments. “Paul Dick was a brilliant businessman, but the whole family also lived very frugally,” recalls Wilhelm Leuze, “so Paul Dick usually came to the company on foot and hardly ever used his company car. As a result, major investments were rare.” Wilhelm Leuze had a different philosophy and expanded the chef’s knife division in particular and upgraded production. Today, these investments are proving to be a smart move: the “chef’s knives” product group is now one of the company’s most important.

Friedr. Dick goes USA – Friedr. Dick Corp. is founded

Once again, Friedr. Dick ventures across the pond. In 1992, a sales office is opened in Farmingdale, New York, to better serve the land of opportunity. Over the years, many strategic partnerships have developed in the USA, which now need to be expanded and utilized.

Acquisition of von den Steinen, Remscheid: manufacture of circular knives and sawing machines

With the takeover of the von den Steinen company in Remscheid, Friedr. Dick secured further leadership in the circular knife sector. This was because von den Steinen and Wilh. Meeh were the most important manufacturers of circular tools. As no successor could be found at von den Steinen either, Friedr. Dick decided to take over the company.

Together we are better than alone: file production is relocated to Switzerland

In view of the long tradition of file production at Friedr. Dick, the decision to discontinue file production in Esslingen was not an easy one. Friedr. Dick had already been working with a Swiss company as a manufacturing partner for many years, particularly in the field of precision files. Both companies followed the development of the market closely and critically, as files were needed less and less due to increasing automation. In 1993, the decision was made to pool capacities and merge the production of the two companies. Together, they were able to significantly increase production volumes and the file business remained successful.

Our own sales office in Milan, Italy

Italy has always been an exciting and successful market for Friedr. Dick. Not least because of an excellent representative who sold Friedr. Dick’s products in Italy. However, after this representative retired, a decision had to be made as to how sales in Italy should be organized in the future. Those responsible around Wilhelm Leuze saw great potential for their products in the Italian market and decided to set up their own sales office and continue successful sales.

1997

1997Relocation from Esslingen to Deizisau

The company premises in Esslingen have been home to Friedr. Dick for more than 100 years. This made the decision to leave the site and move to Deizisau, about 10 km away, all the more difficult. In the meantime, the premises in Esslingen were not only too large, but also impractical and inconvenient for modern production processes. After much deliberation, a factory building was found in Deizisau that met Friedr. Dick’s requirements. In the summer of 1997, the suitcases were packed and first the administration and production, then the warehouse and the entire company moved to Deizisau. However, it was Wilhelm Leuze’s personal wish that the former listed company building in the heart of Esslingen should not stand empty and fall into disrepair, but should remain part of the town. This wish became reality: to this day, the building is home to a shopping and experience center called “Das DICK”.

2010

2010State-of-the-art modernization

The production of chef’s and butcher’s knives continues to grow. F. DICK products have made a name for themselves worldwide, not least because of their absolute professional quality. For this reason, knife production has been further modernized and production has been upgraded to the latest state of the art. In addition to traditional manual work, highly automated production robots are now increasingly being used. Friedr. Dick relies on a combination of experienced employees and innovative robot technology.

The intelligent knife for the food industry

Another innovation reaches market maturity: the RFID system for the meat and food industry is distributed via the newly founded, wholly owned subsidiary RFIDICK GmbH. This enables complete traceability of tools in production and ensures greater safety. The system has a modular structure and can be flexibly adapted to suit local conditions and requirements.

2017

2017Change at the top of the company – Steffen Uebele becomes Managing Director

After almost 30 years at the helm of the long-established company, Wilhelm Leuze will hand over the management of the company to Steffen Uebele in the course of 2017. Mr. Uebele has already been responsible for the international sales of the “Knives and Machines” division for several years and is now taking over the management of the entire company. Friedr. Dick remains family-owned.

DO YOU NEED MORE INFORMATION?

With our RFID technology, we offer a solution that enables clear allocation in the event of damage. The contactless, automatic identification and tracking of tools allows them to be located quickly and efficiently, resulting in effective management and a reduction in losses.

Contact us